- All Cutting Tools

- (TA)0 degree Turning

- (T)10 degree Turning

- (UT)21 degree Turning

- (U)47 degree Turning

- (UQ)50 degree Turning

- (G)Grooving

- (GQ)Round Grooving

- (i)Threading

- (D)Face Grooving

- (DQ)Round Face Grooving

- (V)Camshaft Grooving

- (B)Back Turning

- (H)Through Coolant T

- (H)Through Coolant UQ

- (DC)Double Cutting Edge

- (S)Customized Tools

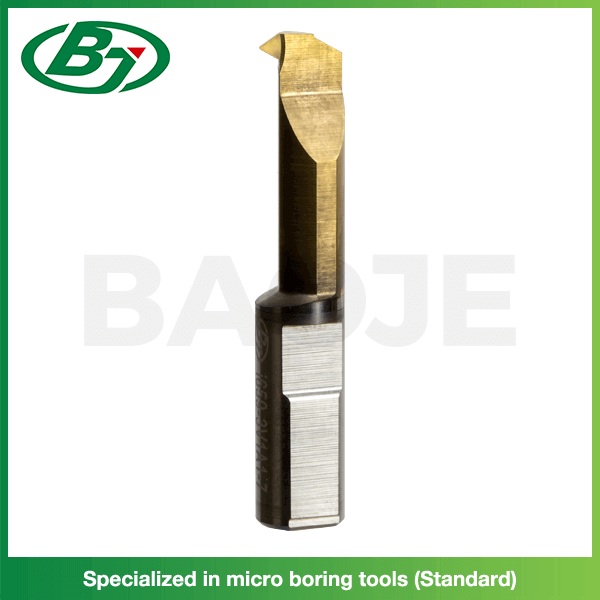

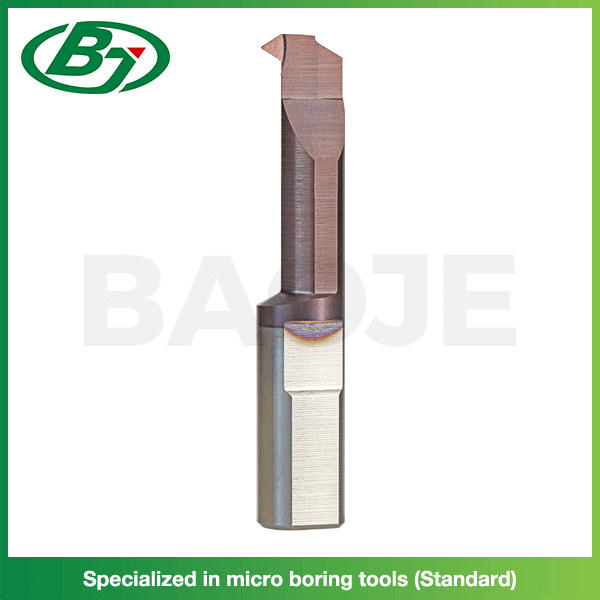

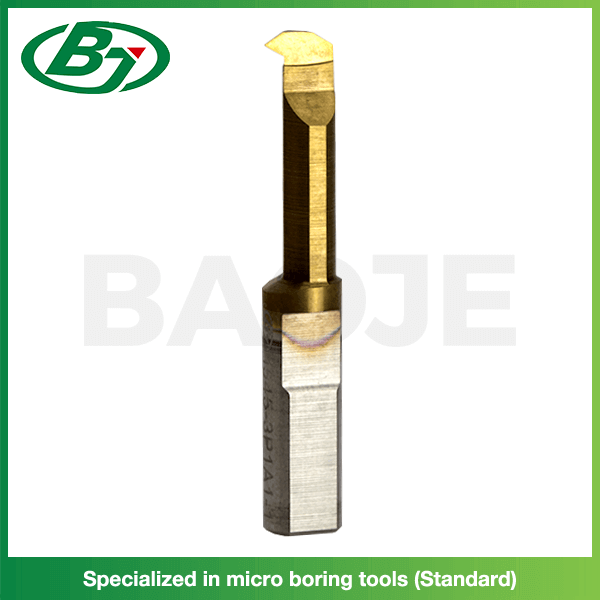

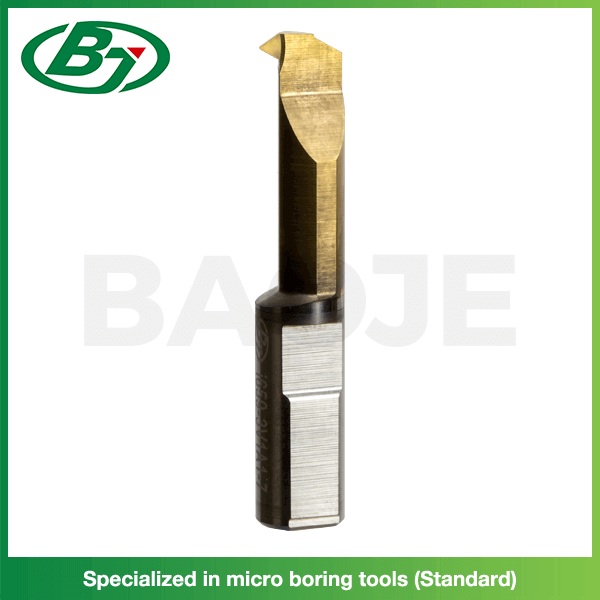

(i)Threading

Specifications:

0.6mm~ 8mm. Tungsten carbide materials are imported from Europe and Japan.

Characteristics:

For Rough orprecision cutting use.

Notes:

Coated by imported equipment.

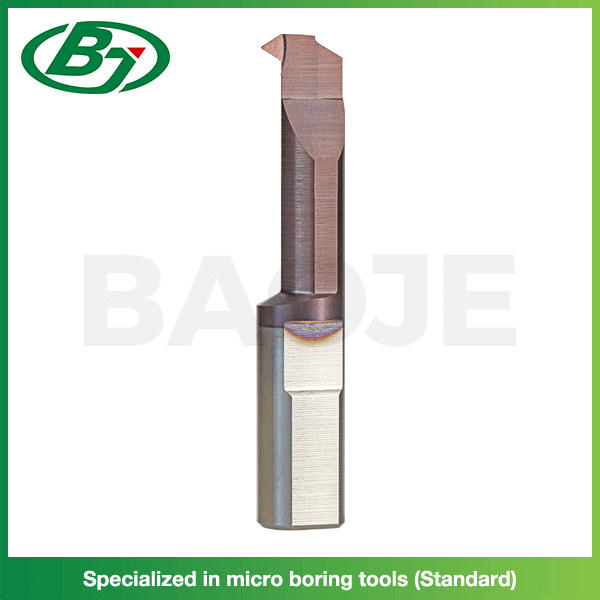

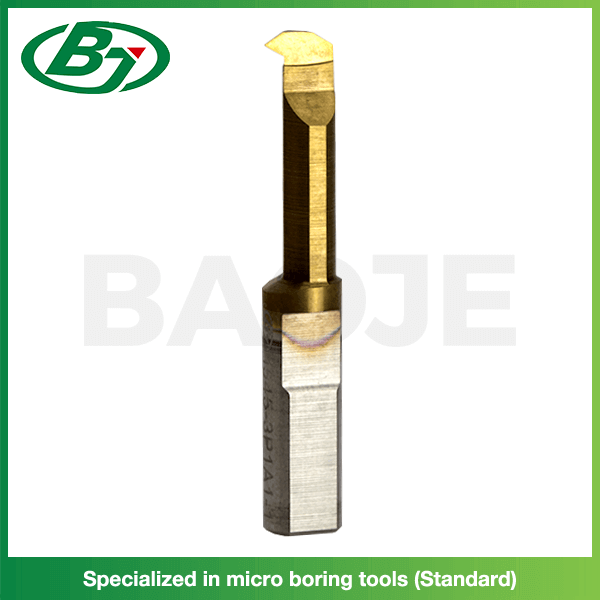

Tungsten Carbide Inner-Hole Threading Tool

Cutting Tool Series

Tungsten carbide inner-hole threading tool normal have two types: one is standard threading tool, the other is general used threading tool; standard threading tool specification is according to threads specification, so standard threading tool can thread completely within one operation, general threading tool does not have inner radius for thread tip so cannot thread completely once so need to machining the thread tip in a second CNC operation.

Threads types are 1. Metric thread (MM thread), 2. American thread (Unified Standard Thread), 3. Pipe thread (BS PT), 4. Pipe thread (PS parallel straight thread), 5. Pipe thread (US NPT), 6. Trapezoidal thread (30 degree metric system), 7. Trapezoidal thread (29 degree Ekham thread)

Triangular thread is also named V thread, the triangular thread is often used in machine parts due to easier threaded, very widely used, is the most used thread type, there are many triangular threading methods, CNC threading is one of the methods.

Select suitable threading tool to thread workpiece according to thread specification, workpiece material, machining method, tool path and machining conditions.

Need to take care on feed rate, cutting amount and the main spindle RPM during the threading process to ensure thread quality is accepted by thread plug gage.

How to use Baoje inner-hole threading tool

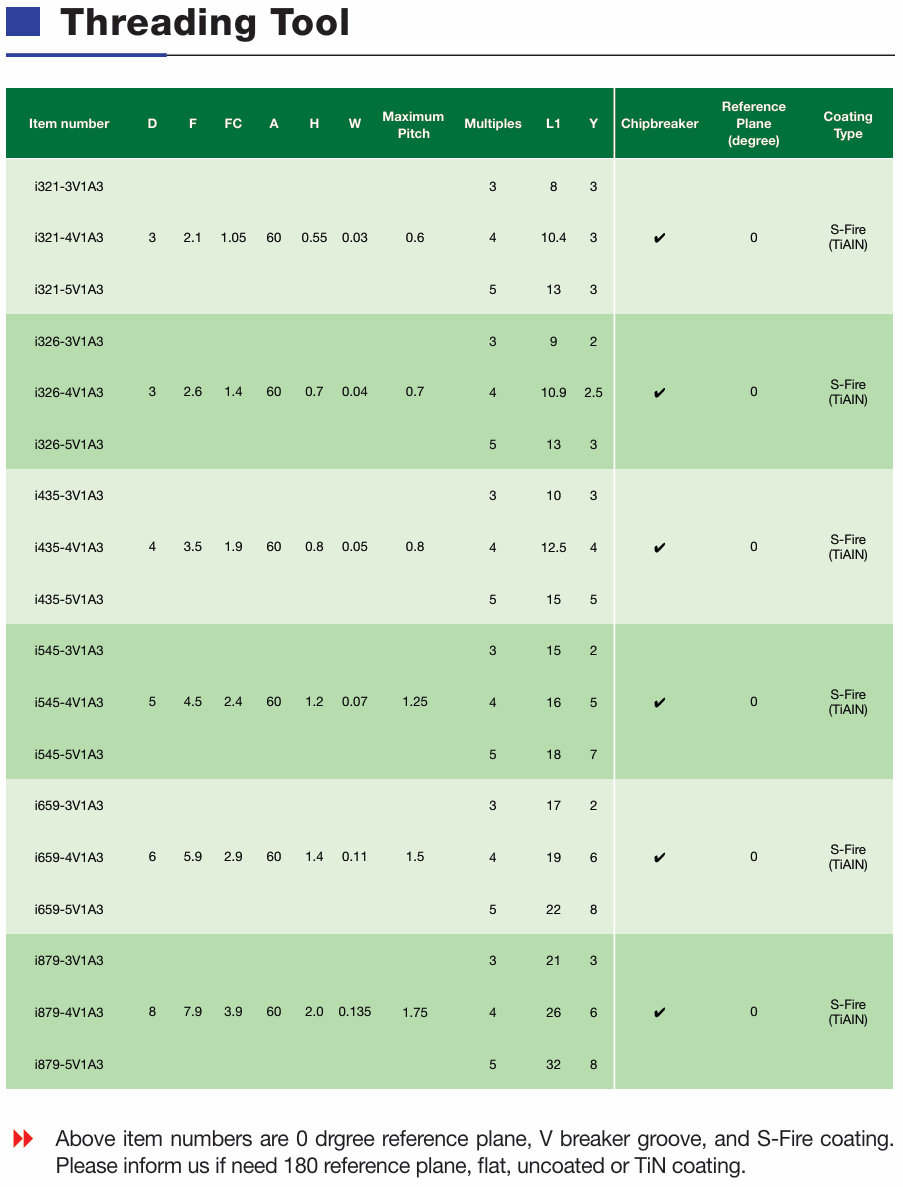

Baoje Tungsten carbide inner-hole threading specializes micro inner-hole machining have standard general threading tool and customized threading tool, we normally provide in tungsten carbide shafts in Φ3 /Φ4 / Φ5 / Φ6 and we do customize Φ8 shaft when is necessary and required.

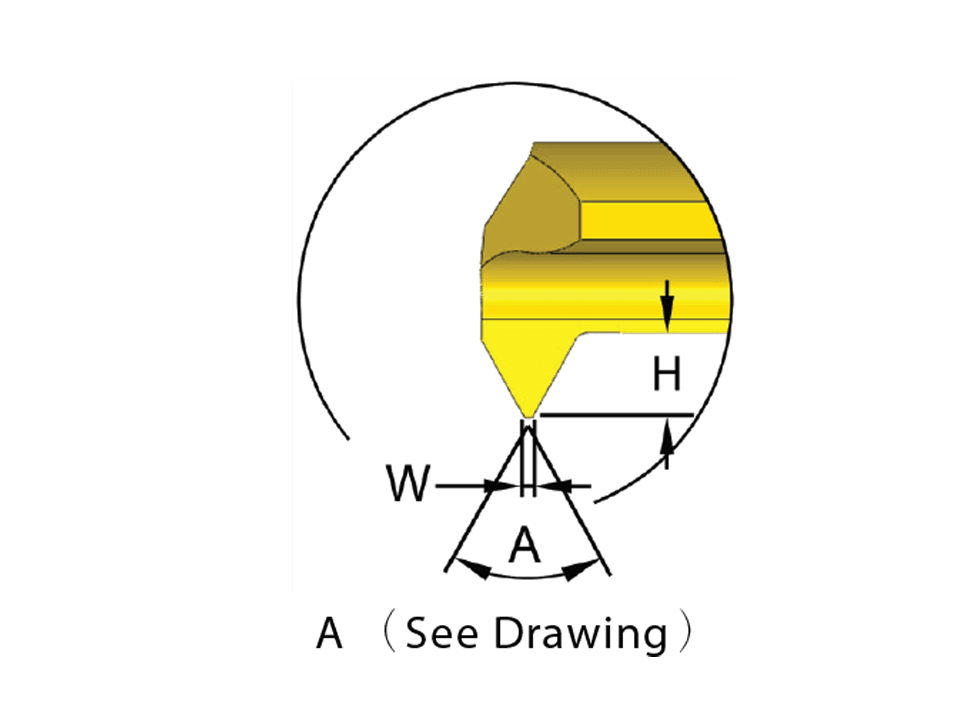

Baoje provided general threading tool are 60 degree threading tool according to workpiece common threading requirements, also called V type threading tool, we do provide threading tools with pitches: 0.6 mm/0.7 mm/0.8 mm/1.25 mm/1.5 mm.

Baoje provides suitable customized inner-hole threading tools according to threading requirements like: thread type, thread pitch, thread shape, workpiece machining drawing, workpiece material designation, machining method and tool path.

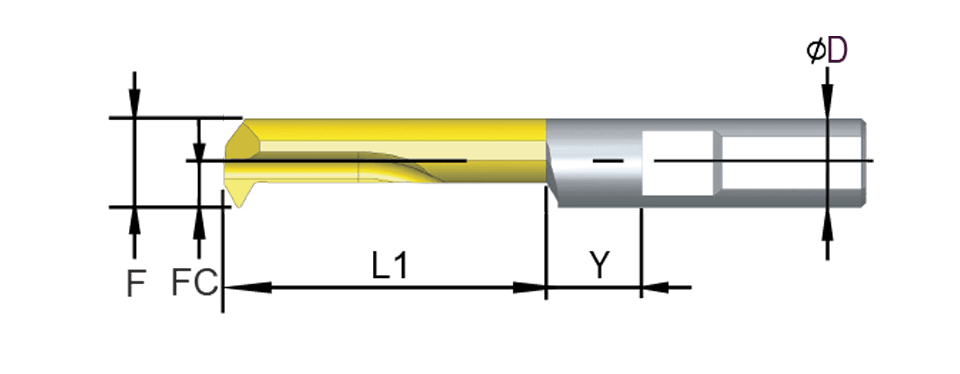

We do customize the above tool every dimensions including F / FC / L1 / L2 / W / H / A° / ΦD / Tip Radius, according to your requirement beside standard threading tool.

Videos

Superior techniques, premium quality adherence.

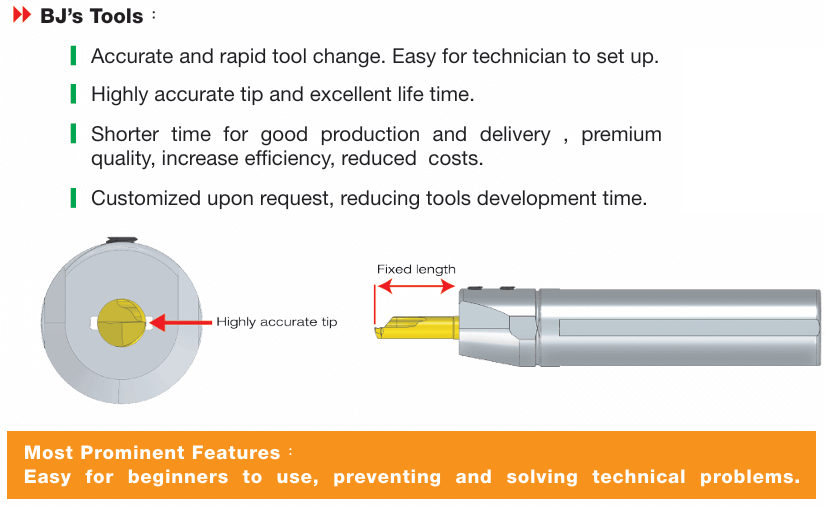

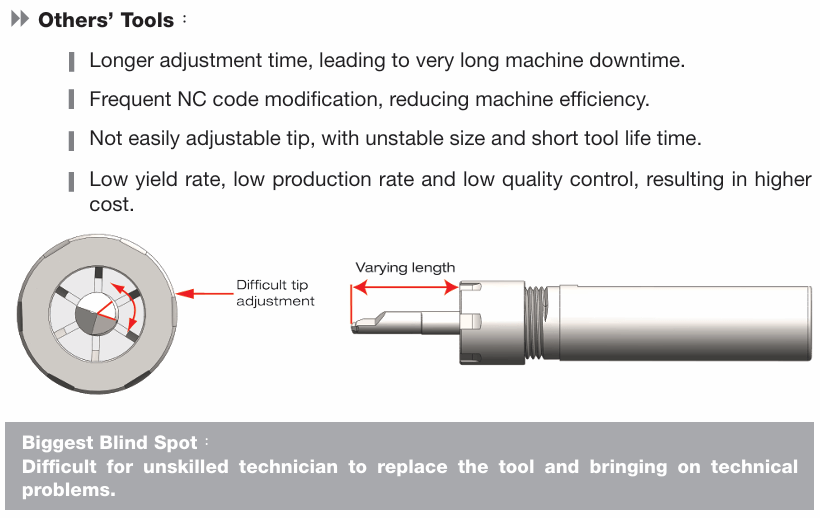

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.