- All Cutting Tools

- (TA)0 degree Turning

- (T)10 degree Turning

- (UT)21 degree Turning

- (U)47 degree Turning

- (UQ)50 degree Turning

- (G)Grooving

- (GQ)Round Grooving

- (i)Threading

- (D)Face Grooving

- (DQ)Round Face Grooving

- (V)Camshaft Grooving

- (B)Back Turning

- (H)Through Coolant T

- (H)Through Coolant UQ

- (DC)Double Cutting Edge

- (S)Customized Tools

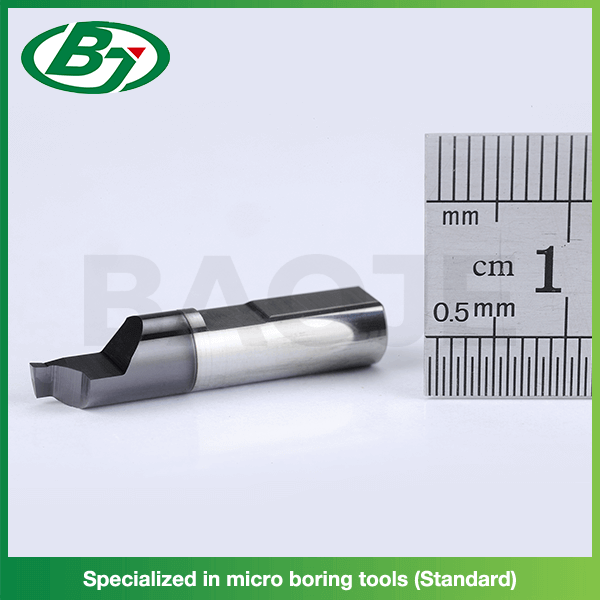

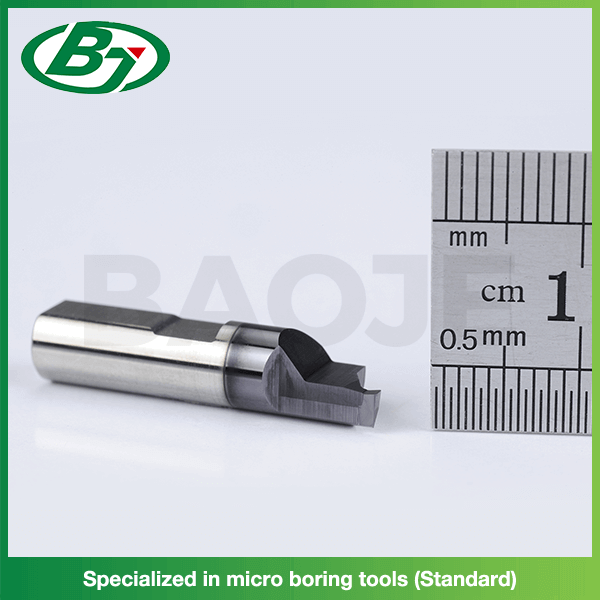

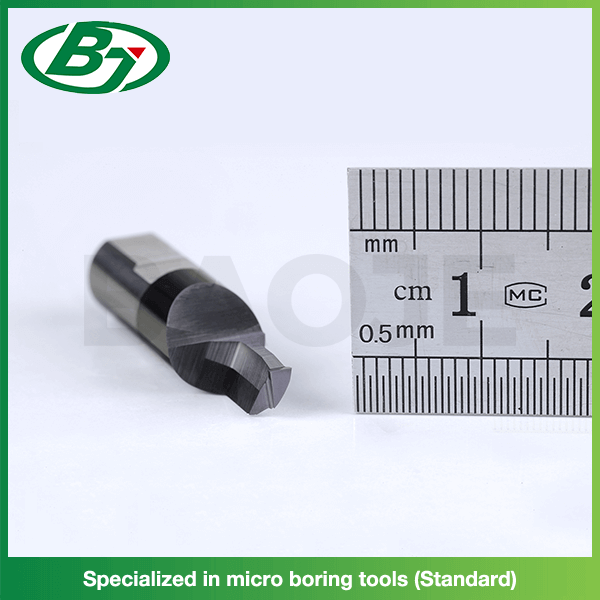

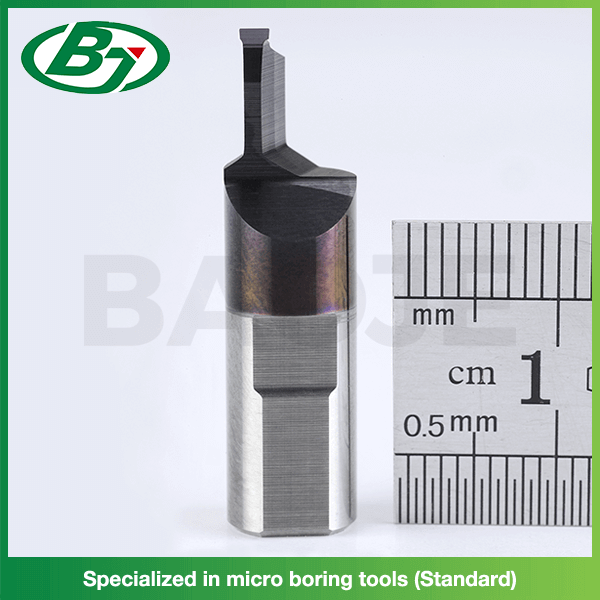

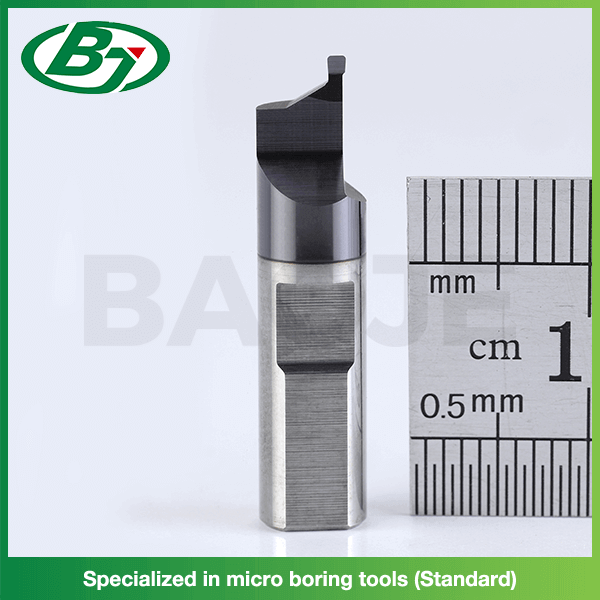

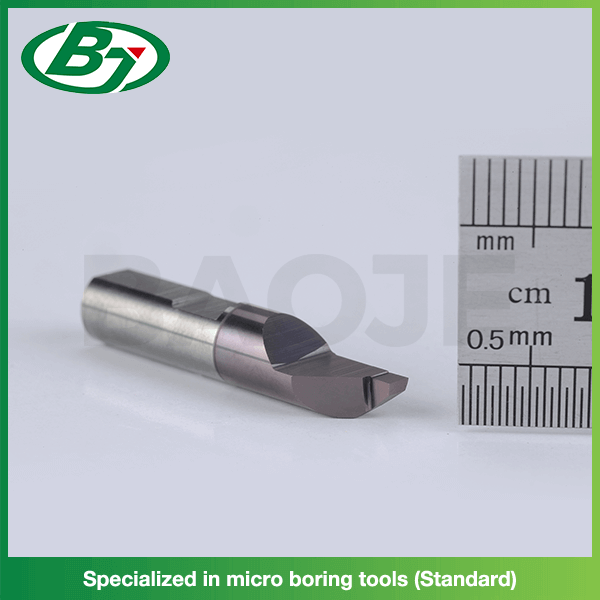

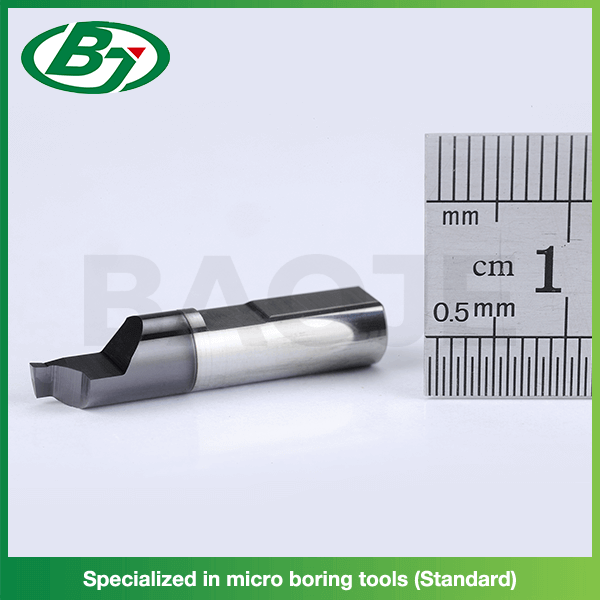

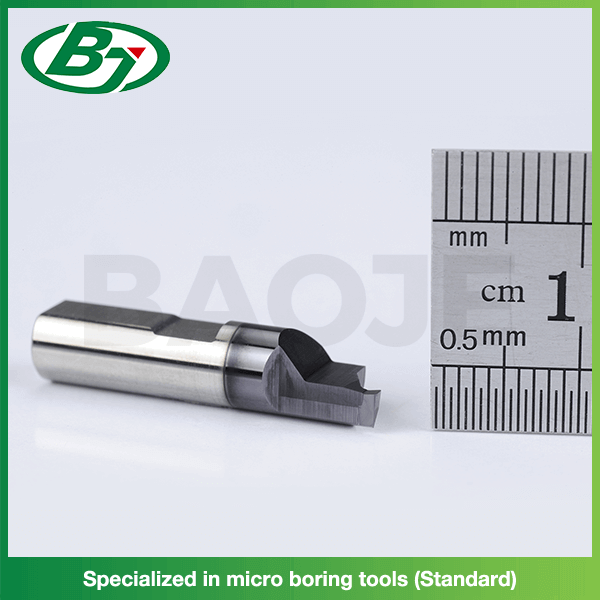

(D)Face Grooving

Specifications:

0.2mm~ 8mm.Tungsten carbide materials are imported from Europe and Japan.

Characteristics:

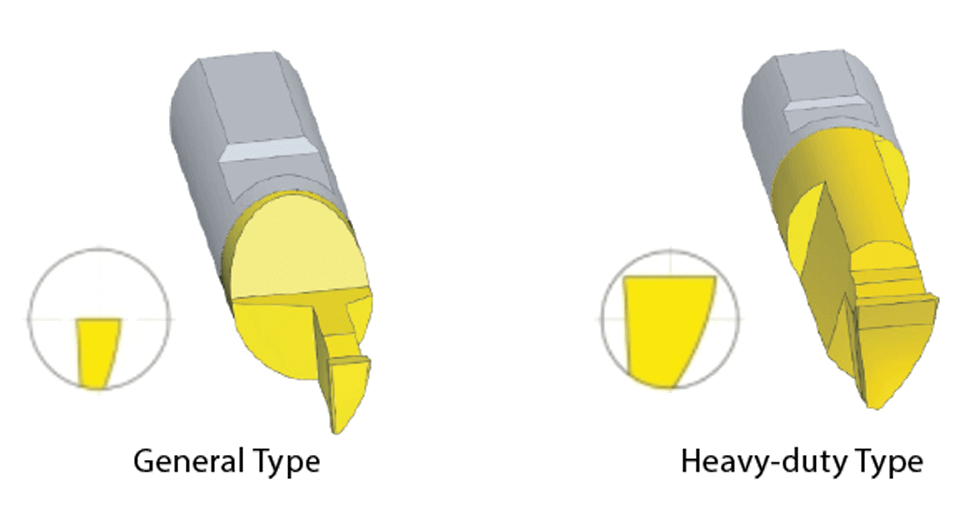

General and Heavy-duty Type.

Notes:

We provide over 3000 type of customized face grooving tools and over 95% success cases.

Face Grooving Tool

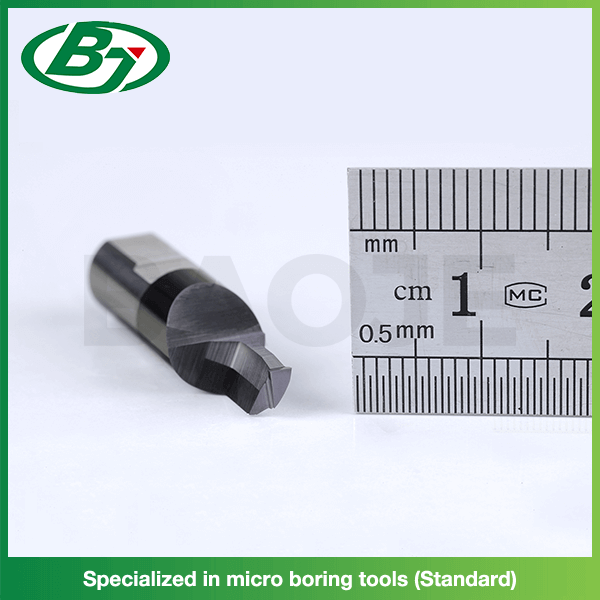

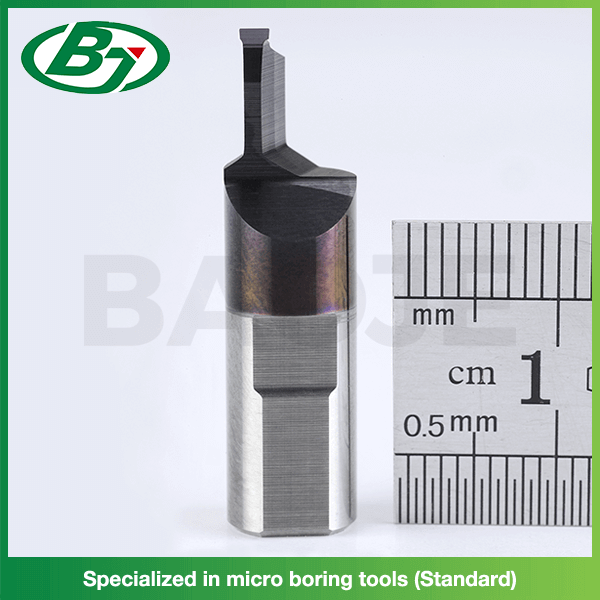

Tungsten Carbide Face Grooving Tool

BJ Tungsten Carbide face grooving tool, commercial ISO face tool are shallow face tool and deep face tool.

The face grooving tool both front cutting tips can be designed to be with radius or chamfer according to customer machining requirements.

Face grooving tool will machine off more material during machining process, so if not properly designed might happen/occur the following situation:

1.When the tool extended L1 length too long will cause broken tool tip or tool vibration during machining due to high machining torque applied to tool tip.

2.The face grooving tool face width designed too big that machines workpiece material too much and having tool oscillating that causes obvious workpiece surface machining patterns.

3.Grooving tool bottom clearance angle designed too narrow will cause machining rigidity.

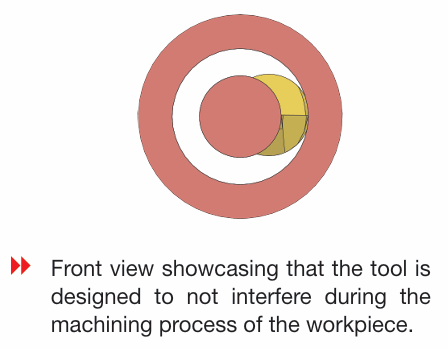

4.Grooving tool bottom clearance angle designed too thick will interfere with workpiece and/or cause insufficient chip space.

How to use Baoje Tungsten Carbide face grooving tool

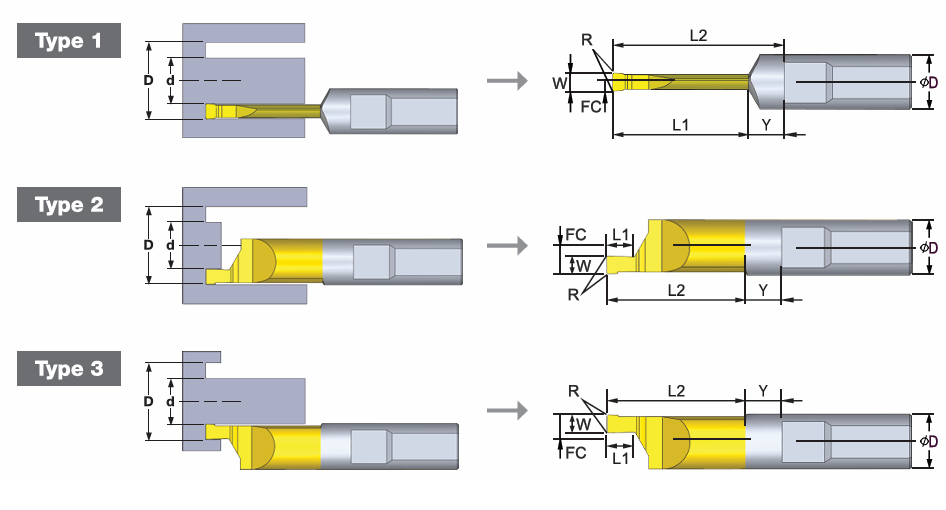

BJ Standard face grooving tool is Φ6 and BJ have 3 type of face grooving tool.

Please kindly review our standard items.

We can provide customized face grooving tool and provide Φ3 / Φ4 / Φ5 / Φ6 / Φ8.

Why to use Baoje customized face grooving tool

1.Baoje face grooving tool designed 0 degree and 180 degree tool type according to customer confortable tightening procedures, determine grooving tool bottom clearance angle according to workpiece groove outside and inside diameters to avoid interferences during machining process and inefficient tool stiffness.

2.If face grooving machining is with strong machining resistance and oscillates during machining process, Baoje designed special high rigidity face grooving tool and toolholder.

3.According to the workpiece material specification customize required tool path.

4.Can equip with different special toolholder for different types of CNC lathes.

5.Baoje developed angled face groove tool, normally when face grooving tool extending long will cause tool oscillating, angled face grooving tool decreases extended length to stop tool oscillating and blind spot machining concern.

6.Provide round nose face grooving tool and forming face grooving tool.

Baoje forming face grooving tool is well designed that included with grooving, machining and face machining etc. three functions, with this one tool can perform roughing, chip evacuation and finishing, optimize your machining process and is the first selected face grooving tool supplier in Taiwan CNC Lathes industrial.

Customization specifications

We do customize face grooving tool with the above tool every dimensions including FC / L1 / L2 / W / ΦD / Tip Radius, according to your requirement.

Videos

Superior techniques, premium quality adherence.

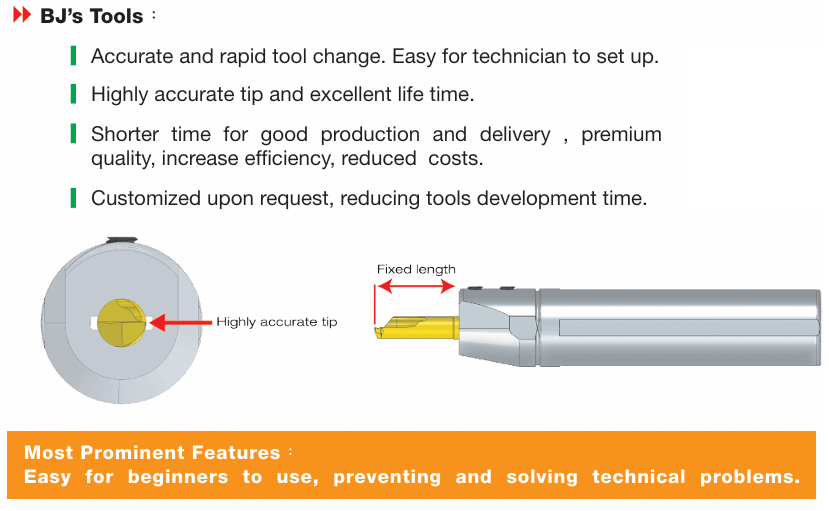

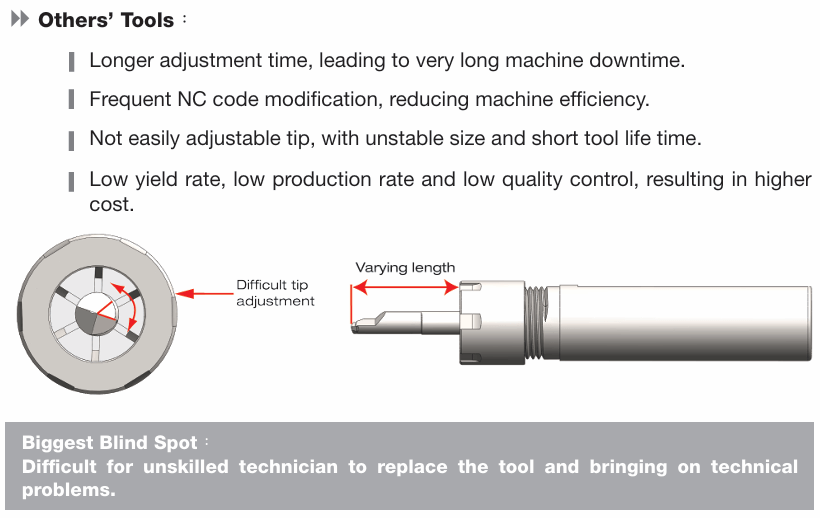

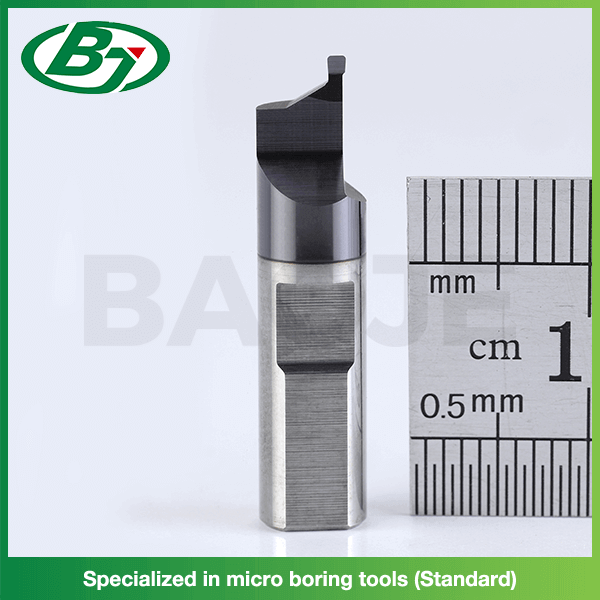

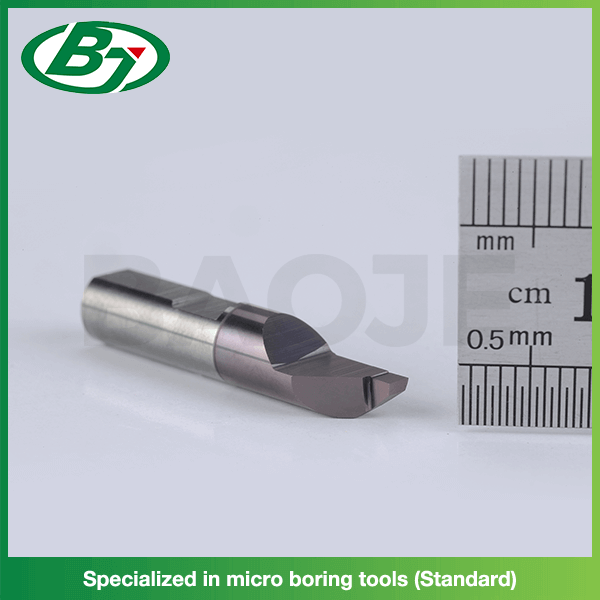

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.