Name

Rigid Face Grooving tool

Application

Electrooptics precision parts ( Difficulties:Tight Roughness and tolerance requirements. ) Cutting Material:DHS-1.

Description

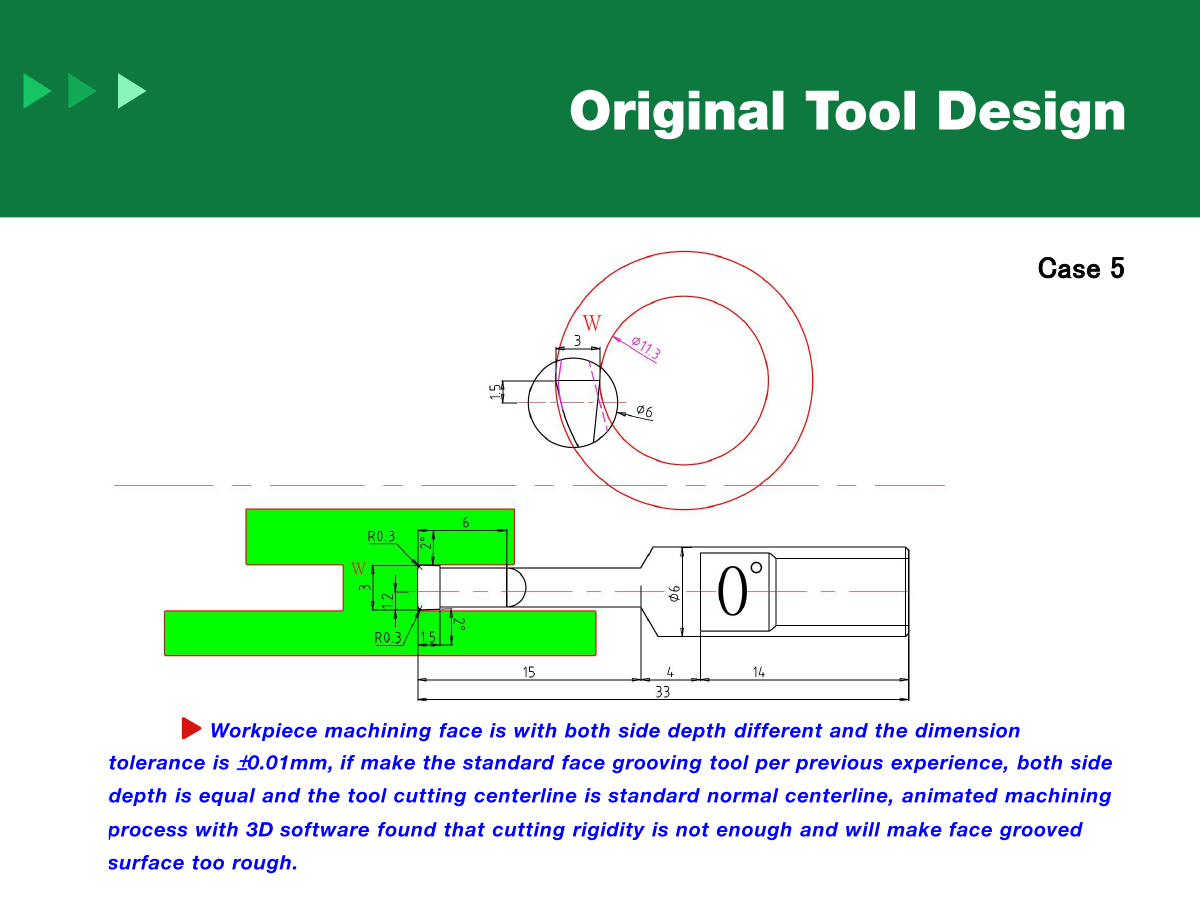

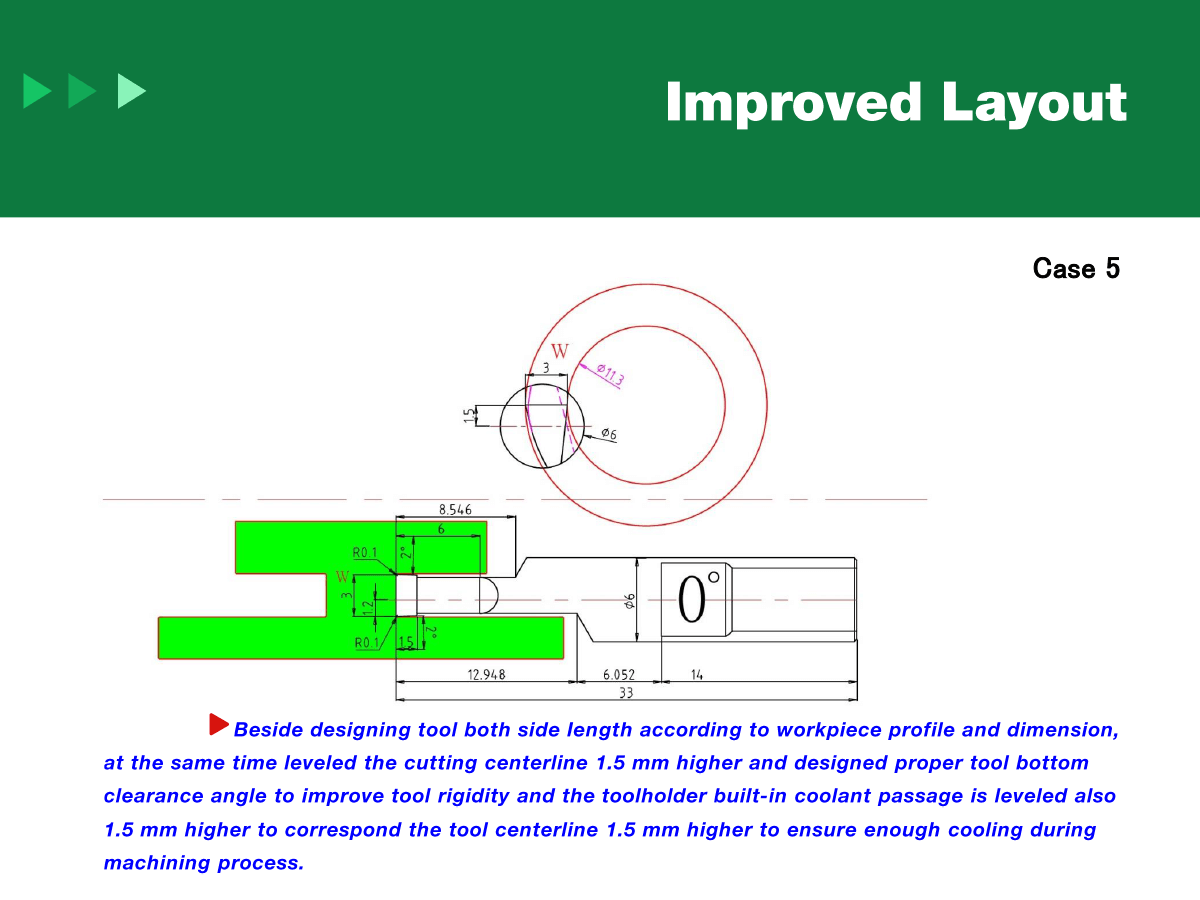

Workpiece machining face is with both side depth different and the dimension tolerance is ±0.01mm, if make the standard face grooving tool per previous experience, both side depth is equal and the tool cutting centerline is standard normal centerline, animated machining process with 3D software found that cutting rigidity is not enough and will make face grooved surface too rough. Beside designing tool both side length according to workpiece profile and dimension, at the same time leveled the cutting centerline 1.5 mm higher and designed proper tool bottom clearance angle to improve tool rigidity and the toolholder built-in coolant passage is leveled also 1.5 mm higher to correspond the tool centerline 1.5 mm higher to ensure enough cooling during machining process.

Superior techniques, premium quality adherence.

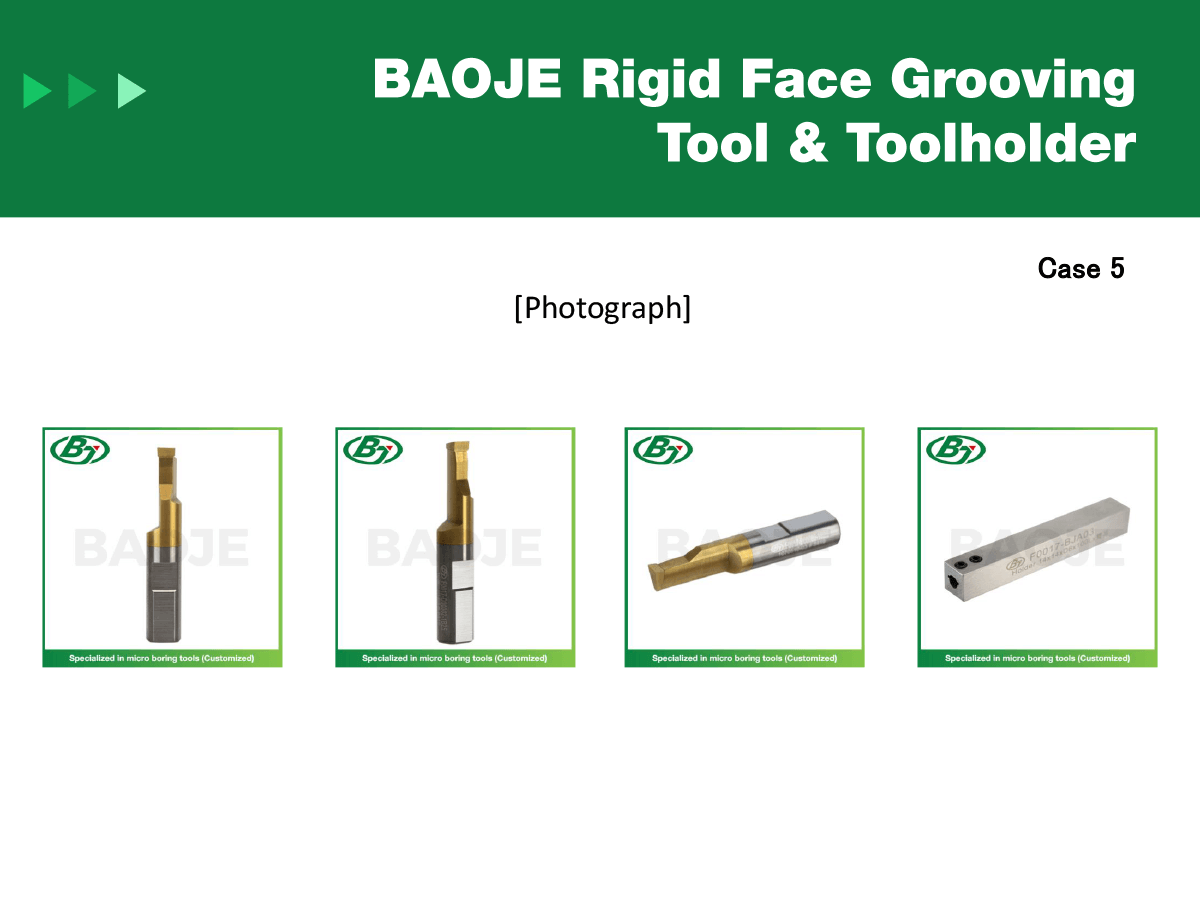

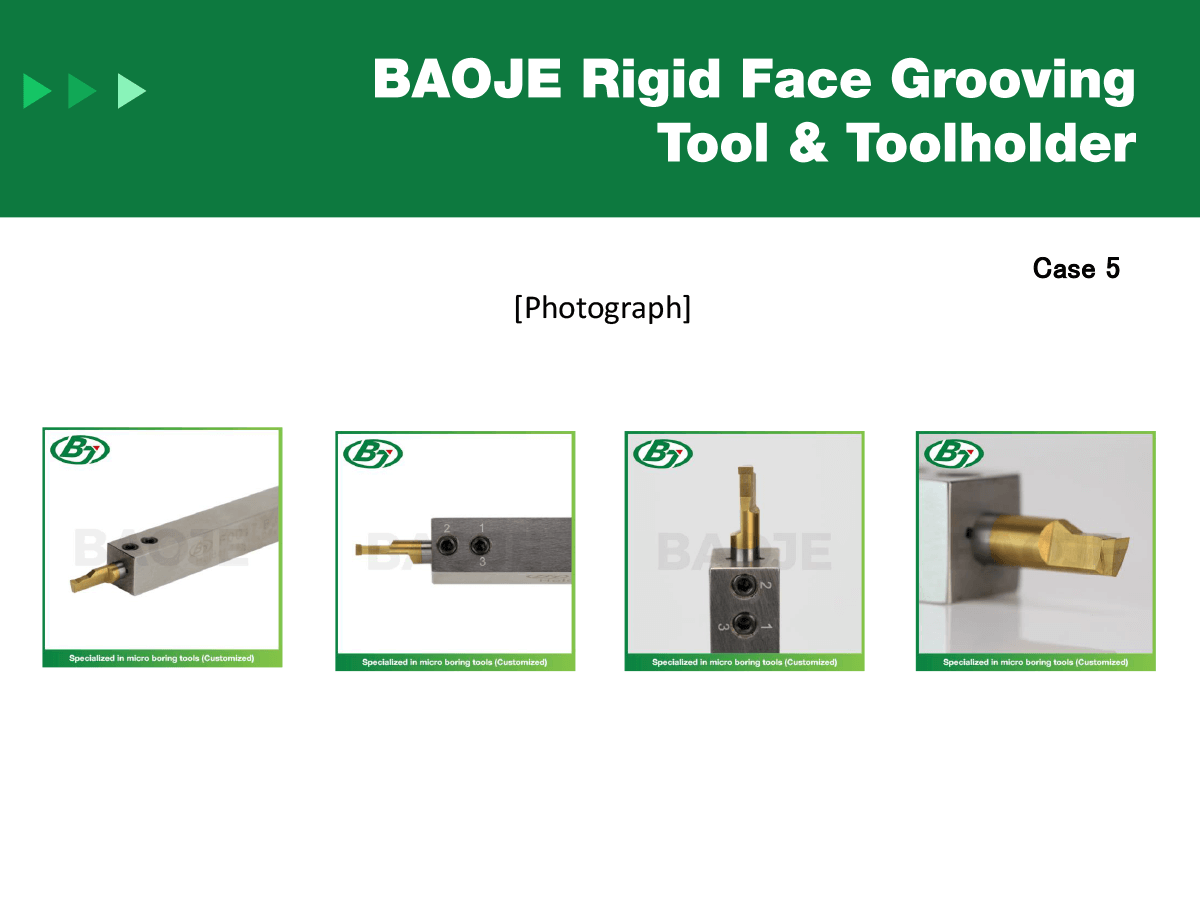

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.

Superior techniques, premium quality adherence.

BAOJE industrial Ltd. Co. is a leading manufacturer of high quality micro boring tools with 30 years experience. We focus on what you need and endeavor to research the best quality of tools for your industry. These are some patents which include CNC grinding tool machine, sectioning machine, precision boring tools along with toolholders to satisfy your needs.